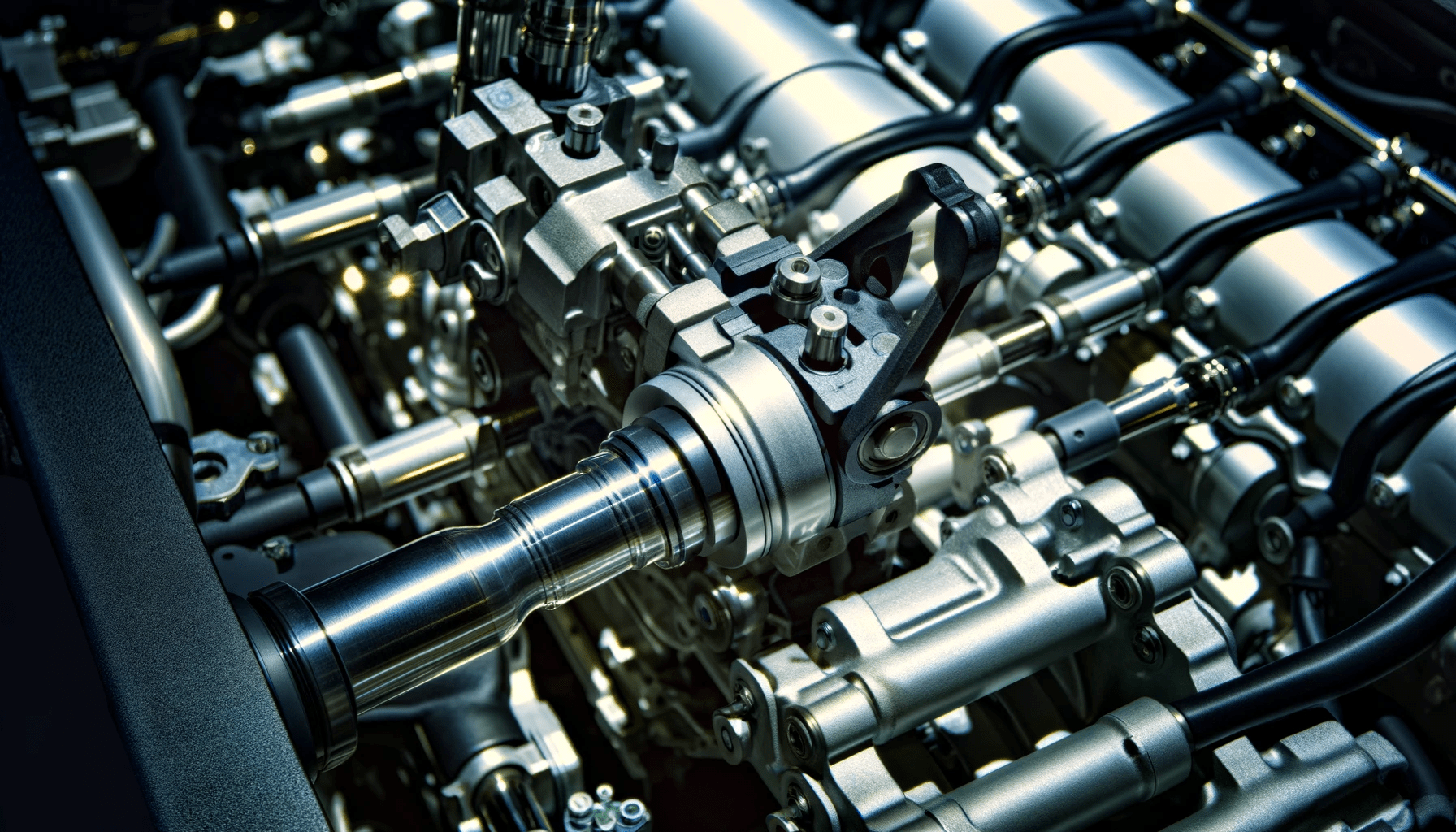

In the realm of heavy-duty trucks, fuel injection pumps play a crucial role in ensuring optimal engine performance. These pumps are responsible for delivering fuel to the engine cylinders at the right pressure and timing, making them integral components of diesel engines. However, like any mechanical part, fuel injection pumps are prone to various issues that can disrupt truck operation and efficiency. Understanding these common problems and their solutions is essential for truck owners and operators to maintain their vehicles’ reliability and performance.

Introduction to Fuel Injection Pumps:

Fuel injection pumps are intricate mechanical devices designed to deliver precise amounts of fuel to the engine cylinders. In diesel engines, these pumps pressurize the fuel and deliver it in a fine mist to facilitate combustion. There are several types of fuel injection systems used in trucks, including rotary pumps, inline pumps, distributor pumps, and common rail systems. Each system operates differently but serves the same purpose of delivering fuel efficiently to the engine.

Common Issues with Truck Fuel Injection Pumps:

Poor Fuel Economy: One of the most noticeable signs of a failing fuel injection pump is a decrease in fuel efficiency. If the pump is not delivering fuel properly, the engine may consume more fuel than necessary, resulting in decreased mileage.

Hard Starting or No Start: A faulty fuel injection pump can cause difficulties in starting the engine or prevent it from starting altogether. This issue may stem from insufficient fuel delivery or air entering the fuel system, leading to inadequate combustion.

Engine Misfires: When the fuel injection pump fails to deliver fuel consistently, the engine may experience misfires or rough idling. This can be attributed to uneven fuel distribution among the cylinders, resulting in incomplete combustion.

Loss of Power: A malfunctioning fuel injection pump can lead to a loss of engine power, especially during acceleration or under load. Insufficient fuel delivery can cause the engine to struggle to generate the required power, affecting overall performance.

Excessive Smoke: Excessive smoke emissions from the exhaust can indicate a problem with the fuel injection pump. Over-fueling or improper fuel atomization can result in unburned fuel being expelled as smoke, leading to increased emissions and environmental pollution.

Fuel Leaks: Fuel leaks around the injection pump or fuel lines are common issues that can arise due to worn seals, cracked lines, or loose fittings. These leaks not only waste fuel but also pose a fire hazard and should be addressed promptly.

Increased Engine Noise: A failing fuel injection pump may produce unusual noises such as knocking, ticking, or whining. These noises can indicate internal wear or damage within the pump, necessitating inspection and repair.

Tips and Solutions:

- Regular Maintenance: Proper maintenance is key to preventing fuel injection pump issues. Regularly inspecting and servicing the fuel system, including filters, lines, and injectors, can help identify and address potential problems before they escalate.

- Use High-Quality Fuel: Using clean, high-quality diesel fuel is essential for ensuring the longevity and performance of fuel injection pumps. Contaminated or low-quality fuel can cause premature wear and damage to pump components.

- Monitor Fuel Pressure: Monitoring fuel pressure is crucial for detecting fuel system issues early on. Installing a fuel pressure gauge allows truck owners to monitor fuel pressure levels and identify abnormalities that may indicate pump problems.

- Address Fuel Contamination: Diesel fuel contamination, such as water or debris, can damage fuel injection pumps and other engine components. Implementing proper fuel storage and filtration systems can help prevent contamination and maintain fuel system integrity.

- Seek Professional Assistance: When faced with fuel injection pump issues beyond your expertise, it’s essential to seek professional assistance. Qualified diesel mechanics have the knowledge and tools to diagnose and repair complex fuel system problems effectively.

- Consider Pump Replacement: In cases of severe pump damage or wear, replacement may be the most cost-effective solution. Investing in a high-quality replacement pump from a reputable manufacturer ensures reliable performance and longevity.

- Check for Air Leaks: Air leaks in the fuel system can disrupt fuel delivery and lead to engine performance issues. Inspect fuel lines, connections, and seals for signs of leaks, and repair or replace any damaged components to prevent air ingress into the system.

- Clean or Replace Filters Regularly: Fuel filters play a vital role in trapping contaminants and preventing them from reaching the fuel injection pump and engine. Regularly clean or replace fuel filters according to the manufacturer’s recommendations to ensure optimal fuel system performance and longevity.

- Optimize Fuel Injector Performance: Fuel injectors work in tandem with the fuel injection pump to deliver fuel to the engine cylinders. Over time, fuel injectors can become clogged or worn, affecting fuel delivery and engine performance. Consider periodic cleaning or professional servicing of fuel injectors to maintain their efficiency.

- Use Fuel Additives: Fuel additives can help improve fuel quality, lubricate fuel system components, and reduce carbon buildup in the engine. Consider adding a high-quality fuel additive to your diesel fuel periodically to enhance fuel system performance and prolong the life of fuel injection pumps.

- Monitor Engine Temperature: Excessive heat can accelerate wear and damage to fuel system components, including fuel injection pumps. Monitor engine temperature regularly and address any overheating issues promptly to prevent potential damage to the fuel system.

- Inspect Fuel Tank and Lines: Regularly inspect the fuel tank and lines for signs of corrosion, damage, or contamination. Clean and repair or replace any corroded or damaged components to prevent fuel system issues and ensure proper fuel flow to the injection pump.

- Implement Fuel System Flush: Periodically flushing the fuel system can help remove accumulated deposits, contaminants, and water from the fuel lines, tank, and injection pump. Consider scheduling a professional fuel system flush as part of your routine maintenance to maintain fuel system integrity and performance.

Conclusion:

In conclusion, fuel injection pump issues can significantly impact the performance and reliability of truck engines. By understanding the common problems associated with fuel injection pumps and implementing preventive maintenance measures, truck owners can mitigate these issues and prolong the life of their vehicles. Regular maintenance, monitoring fuel pressure, using high-quality fuel, and seeking professional assistance when needed are essential practices for ensuring optimal fuel system performance. For truck owners in Texas looking to buy fuel injection pumps or seeking reliable fuel injection pump sellers, Black Diamond Unlimited offers top-quality products and services to meet their needs. With a commitment to excellence and customer satisfaction, Black Diamond Unlimited is a trusted source for fuel injection pumps in Texas.

Leave a comment

Your email address will not be published. Required fields are marked *